In the rapidly evolving landscape of the pharmaceutical industry, the importance of integrating state-of-the-art technology into Pharma Equipment has never been more critical. As we step into 2024, the push for enhanced efficiency and stringent compliance has prompted a wave of innovations that are transforming the way pharmaceutical equipment operates. These advancements not only streamline production processes but also ensure that companies meet regulatory standards more effectively. The advent of digital tools and smart technologies facilitates better data management and operational oversight, paving the way for a more agile and responsive manufacturing environment. As we explore the latest trends and breakthroughs in Pharma Equipment, it becomes evident that these innovations are setting new benchmarks for quality and performance, thereby revolutionizing the pharmaceutical sector.

In 2024, the pharmaceutical manufacturing landscape is being transformed by emerging technologies that enhance both efficiency and compliance. A key driver of this change is the adoption of Pharma 4.0, which integrates advanced manufacturing execution systems (MES) and artificial intelligence (AI) to optimize production processes. Companies are learning valuable lessons from early adopters, highlighting the importance of scalable digital solutions that not only streamline operations but also ensure regulatory compliance. According to recent reports, embracing Pharma 4.0 technologies can lead to significant improvements in production efficiency and data transparency, positioning organizations for long-term success in a rapidly evolving market.

The impact of AI on the pharmaceutical life cycle is profound, influencing areas such as drug discovery, formulation development, and quality control. As per industry analysis, AI-driven solutions have the potential to reduce drug development timelines by up to 30%, fostering faster delivery of therapies to patients. Reports forecast that digital transformation will continue to shape the industry, with strategic investments in AI and automation being crucial for maintaining competitive advantage. The pharmaceutical sector's focus on innovative technologies, including cell and gene therapies, further underscores the need for a proactive approach to manufacturing that can adapt to the complexities of modern drug development.

| Innovation | Description | Impact on Efficiency | Compliance Benefits | Implementation Timeline |

|---|---|---|---|---|

| Automated Sampling Systems | Robotics to sample products at various stages. | Reduces time by 30% during quality checks. | Improves accuracy of compliance documentation. | 2024 |

| IoT-Enabled Manufacturing | Integration of IoT for real-time monitoring. | Increases output by 25% through optimization. | Facilitates proactive compliance reporting. | 2024 |

| Advanced Data Analytics | Utilizing AI to analyze manufacturing data. | Enhances problem detection by 40%. | Identifies compliance risks proactively. | 2024 |

| Smart Packaging Solutions | Packaging that monitors product condition. | Increases shelf life and reduces waste. | Ensures compliance with safety standards. | 2024 |

| VR Training Simulations | Virtual reality training for staff. | Reduces training time by 50%. | Improves knowledge retention for compliance. | 2024 |

As we progress into 2024, the pharmaceutical industry is undergoing a transformation characterized by technology-driven innovations, particularly in the compliance and efficiency of equipment. The global pharmaceutical equipment market is projected to grow from $23.67 billion in 2025 to $38.82 billion by 2032, with a compound annual growth rate (CAGR) of 7.3%. This rapid expansion highlights the increasing importance of automation in ensuring regulatory compliance while enhancing operational efficiency.

Automation is playing a pivotal role in streamlining processes and reducing the risk of human error in pharmaceutical manufacturing. By integrating sophisticated technologies, companies can achieve higher accuracy in production, compliant tracking, and effective data management, ultimately leading to quicker approvals and reduced time-to-market. According to industry reports, automated systems can improve compliance efficiency by up to 50%, making them indispensable in meeting stringent regulations.

Tip: When considering automation solutions, prioritize systems that offer real-time monitoring and analytics to help maintain compliance and optimize production processes.

Moreover, as regulatory requirements become more stringent, leveraging automation can serve as a key differentiator for companies striving to remain competitive. By investing in smart technologies, the pharmaceutical industry can not only fulfill compliance mandates but also enhance productivity, setting the stage for sustainable growth in the coming years.

Tip: Regular training and upskilling of staff on automated systems can greatly increase the effectiveness of these technologies in maintaining compliance standards.

In 2024, the pharmaceutical industry is on the brink of a transformation driven by data analytics and big data technologies. As highlighted in the latest report from Grand View Research, the global big data in healthcare market is expected to reach $68.75 billion by 2028, growing at a CAGR of 17.9%. This surge in investment is pivotal for pharmaceutical equipment manufacturers who are now leveraging data-driven insights to enhance equipment performance, streamline operations, and ensure regulatory compliance.

Through advanced analytics, pharmaceutical companies can track equipment efficiency in real-time, identifying bottlenecks and maintenance needs before they become critical issues. According to a recent study by McKinsey, companies that adopt data-driven decision-making in their operations can improve productivity by up to 20%. By integrating IoT devices with big data analytics, pharma manufacturers can gather actionable insights that revolutionize maintenance schedules and enhance overall equipment effectiveness (OEE). As a result, firms can not only comply with stringent regulations but also significantly reduce operational costs and improve time-to-market for new drugs.

The pharmaceutical industry is increasingly focused on sustainability, seeking innovative solutions that not only enhance operational efficiency but also minimize waste and energy consumption. According to a report by the Pharmaceutical Research and Manufacturers of America (PhRMA), about 75% of pharmaceutical companies are investing in sustainable practices to reduce their environmental footprint. This shift is driven by both regulatory pressures and a growing consumer demand for eco-friendly products.

Innovations in pharma equipment are paving the way towards more sustainable practices. Advanced technologies such as energy-efficient manufacturing processes and closed-loop systems allow for the recycling of materials, significantly reducing waste. The Global Manufacturing and Equipment Report suggests that implementing environmentally friendly equipment can lower energy consumption by up to 30%, translating into substantial cost savings for companies. Furthermore, integrating digital monitoring systems helps track energy use and waste management in real-time, allowing for more informed decisions and continuous improvement.

As the sector evolves, companies that prioritize sustainability in their equipment and practices are not just complying with regulations; they are also positioning themselves as leaders in the market. A recent study by McKinsey & Company indicates that firms with robust sustainability strategies tend to outperform their competitors by as much as 20%. This underscores the transformative potential of investing in sustainable innovations within the pharmaceutical industry, leading to a future that benefits both business and the planet.

The pharmaceutical industry is undergoing significant transformations as regulatory bodies implement new compliance standards in 2024. To navigate this evolving landscape, pharma equipment must adapt to ensure it meets stringent regulations surrounding safety, efficacy, and data integrity. These changes demand not only upgrades in machinery but also enhancements in technologies utilized for monitoring and reporting processes. Equipment that integrates real-time data analytics is becoming essential, allowing manufacturers to maintain compliance effortlessly while optimizing production efficiency.

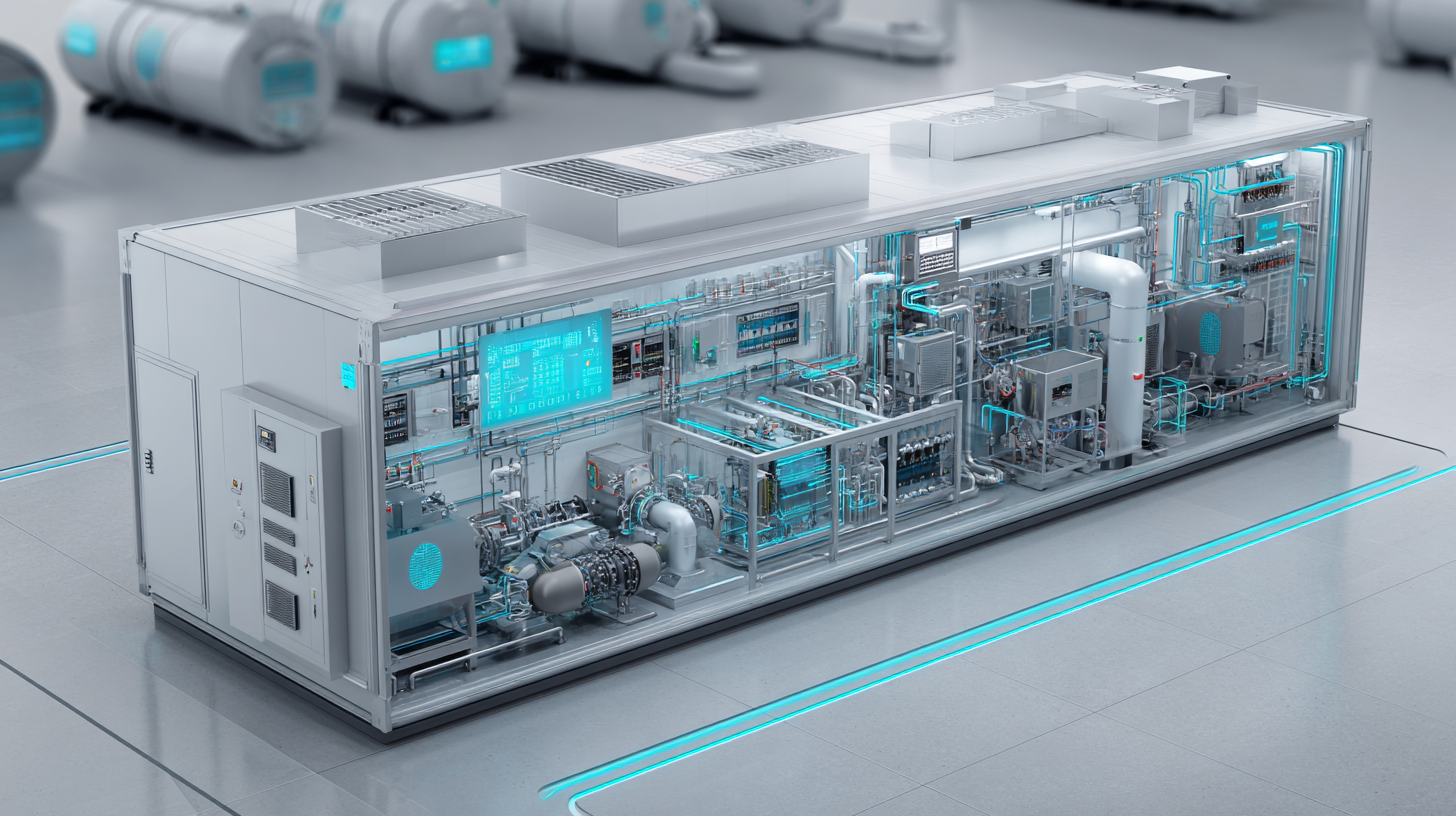

As companies embrace these regulatory changes, innovative solutions are emerging. For instance, automation and digitization of equipment are crucial in maintaining traceability and accountability in the production process. Advanced technologies like artificial intelligence and machine learning offer predictive insights that aid in compliance management, enabling proactive adjustments to manufacturing operations. Furthermore, the development of modular and flexible equipment designs allows for quicker reconfiguration in response to changing regulations, ensuring businesses remain agile and compliant in a dynamic market.