In the realm of waste management, the Sludge Press stands as a crucial tool. According to Dr. Emily Carson, an expert in environmental engineering, “The Sludge Press revolutionizes how we handle waste.” This powerful machine efficiently removes excess water from sludge, transforming it into a more manageable form.

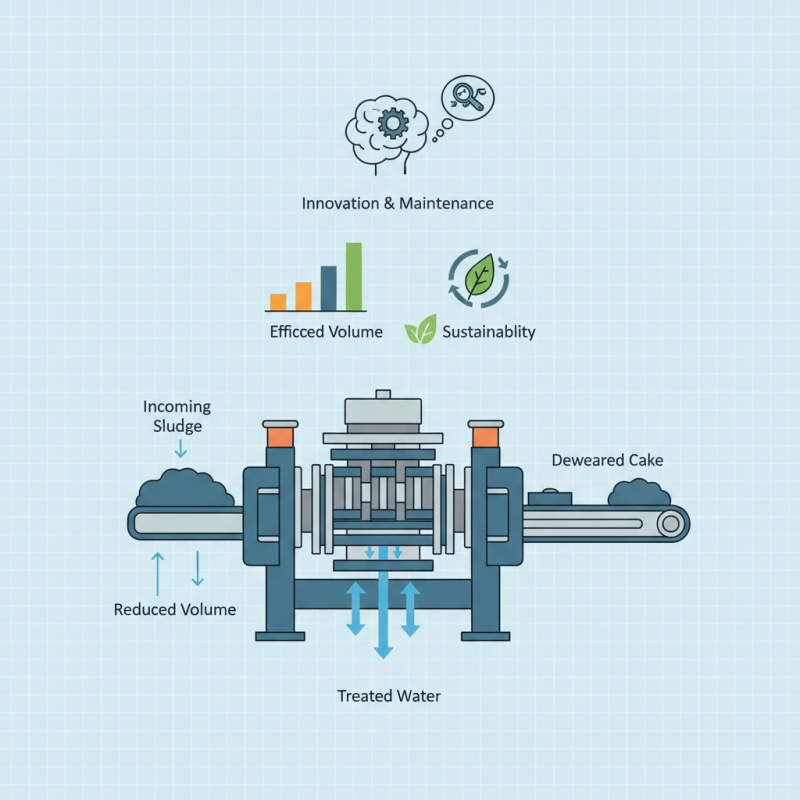

A Sludge Press works by applying significant pressure to sludge, squeezing out moisture. The result is a drier, more compact material. This process not only reduces waste volume but also makes disposal more efficient. However, the technology is not without its challenges. Some plants struggle with maintenance issues, leading to inefficiencies. Regular upkeep is vital for optimal performance.

Dr. Carson emphasizes the need for continuous improvement in the industry. “We must constantly innovate,” she says. By refining the Sludge Press and its applications, we can enhance sustainability efforts in waste management. This dialogue around the Sludge Press highlights both its importance and the room for growth.

A sludge press is an essential piece of equipment in wastewater treatment. It functions by dewatering sludge, which is the residual material from water purification processes. This reduces the volume of waste, making it easier to handle and dispose of. According to the Water Environment Federation, effective sludge treatment can cut down disposal costs by up to 50%.

The process begins when sludge is pumped into the press. An external force is applied, squeezing out the water. This results in a denser material, known as cake, which is more manageable. Research from the American Society of Civil Engineers indicates that dewatering can achieve solid contents up to 30%, which significantly impacts disposal efficiency. However, not all sludge presses operate at peak efficiency; some require continual maintenance to avoid breakdowns.

Understanding the limitations of sludge presses is crucial. They may not fully remove all moisture, leading to heavy residual waste. Industry reports note that poorly maintained units can reduce operational effectiveness by 30%. Operators must regularly monitor performance and make adjustments as needed. This ongoing need for attention reveals the complexity of sludge management systems in achieving optimal results.

A sludge press is a critical component in wastewater treatment. It efficiently removes water from sludge, producing a drier product for further handling. Key components of a sludge press include the feed system, filter plates, and hydraulic system.

The feed system introduces sludge into the press. It ensures uniform distribution. The filter plates, usually made of durable materials, are pivotal. They separate solids from liquids through pressure. This process can achieve a solid content of up to 30%, depending on the sludge type. The hydraulic system controls the pressure, ensuring optimal operation for efficient dewatering.

Tips: Regular maintenance is essential for peak efficiency. Monitor the hydraulic pressure and check filter plates for wear. Small issues can lead to larger inefficiencies. Interestingly, some reports show that poorly maintained systems can reduce output by over 20%.

Overall, understanding these components can aid in successful operation. However, not all systems work seamlessly. Operators should be prepared for troubleshooting. Operator training is vital to handle unexpected situations effectively.

A sludge press is essential for waste management in various industries. It helps in dewatering sludge by pressing the moisture out. Understanding its operation can help optimize efficiency.

During the first step of the process, sludge is pumped into the press from a collection tank. As it enters, a series of conveyor belts may transport it to the pressing chamber. Here, the sludge faces mechanical pressure, which significantly reduces its volume. The sludge cake formed after this process contains much less water.

After pressing, the dewatered sludge is removed. Operators should monitor moisture levels regularly. This ensures the final product meets disposal standards. Small adjustments can greatly enhance performance.

Tips: Regular maintenance of the sludge press can prevent issues. Inspect seals and belts frequently. Monitoring operational parameters ensures optimal performance.

Lastly, remember that each sludge type needs tailored handling. Factors like composition and source can vary widely. This variability requires adaptability in processes. Keeping a flexible approach can lead to better outcomes in sludge management.

| Step | Description | Purpose | Outcome |

|---|---|---|---|

| 1 | Collection of Sludge | Gathering wastewater solids | Preparation for dewatering |

| 2 | Conditioning | Adding chemicals to improve filtration | Enhanced sludge separation |

| 3 | Feeding into Press | Loading conditioned sludge into the press | Initiation of the dewatering process |

| 4 | Dewatering | Applying pressure to separate solids from liquids | Concentrated sludge output |

| 5 | Discharge | Removing dewatered sludge cake | Ready for disposal or further processing |

| 6 | Wash Cycle (if needed) | Cleaning the press to maintain efficiency | Increased equipment longevity |

Sludge presses play a crucial role across various industries, primarily in wastewater treatment. In municipal settings, these machines efficiently remove excess water from sludge. Recent studies indicate that using sludge presses can reduce solid waste volume by approximately 90%. This significant reduction helps lower treatment and disposal costs.

In the food processing industry, sludge presses are essential. They help manage byproducts from food production. According to a report by the Food and Agriculture Organization, nearly 1.3 billion tons of food waste are generated annually. Implementing sludge presses can mitigate this waste, minimizing environmental impact.

Industries like mining also benefit from these presses. They assist in separating valuable minerals from waste materials. A report by the World Mining Congress indicates that about 60% of mining waste is water. Sludge presses can reduce this, promoting sustainable practices. However, challenges remain in optimizing efficiency and reducing energy consumption. Finding the right balance is an ongoing concern for many sectors.

A sludge press is a vital tool in waste management. It efficiently dewaters sludge from various sources. The process involves using pressure to squeeze excess water from the sludge. This results in a more manageable solid that is easier to handle and dispose of.

Using a sludge press has notable benefits:

Tips for effective sludge pressing: